Hardware manufacturers must follow rules and regulations called “hardware safety compliance†to ensure their goods aren’t harmful to people or the environment. Typical areas covered by these rules include product design, production, testing, and labeling, though they differ by country and sector. The existing approaches to ensuring hardware safety compliance have several things that could be improved. The procedure is lengthy and intricate to begin with. Many companies must submit their items to a battery of tests and provide mountains of paperwork to have their items recognized. Secondly, it’s costly. Developing and producing a product can become prohibitively expensive due to compliance requirements. Additionally, there is a high potential for mistakes in the process. Mistakes in documentation or testing can cause delays, or even product recalls when companies make them.

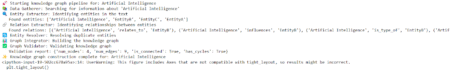

Meet Saphira, a cool AI platform that lays out the details for firms to follow when designing and testing gear to get and stay certified for safety. Saphira is a one-stop shop for all product-related regulations, testing, and standards; it streamlines the process of identifying and prioritizing compliance and safety issues, saving countless dollars and months spent on inefficient safety consultants.

Saphira makes tracking data easier. Engineers’ reports validating compliance with regulations show that features like “the robot arm won’t shock an attendant if touched while in motion†exist. Writing these reports is a real chore. Saphira can automatically generate these reports and even determine whether extra standard clauses apply to each design value or requirement by keeping track of all the relevant source references.

Engineers working for hardware companies of any size can benefit from Saphira. To become certified to operate in the US, the safety engineering team of an industrial robots company might utilize Saphira’s compliance report generator, which includes standards like ISO-12100 and ISO-10219. By using Saphira, a hardware startup’s engineering leader can save months compared to hiring a sluggish safety consultant, which is necessary to obtain UL certs to sell to additional clients. Systems engineers in the aerospace and defense industry can utilize Saphira’s AI tools to comprehend the relevance of different government and military standards (like MIL-STD-810 or ISO-26262) to their specifications and models.

Saphira offers a unified suite of features for improving release cadence, documentation, decision-making, collaboration, time savings, data management, and risk management.

In Conclusion

Hardware firms can enhance their product launch processes with the help of Saphira AI, a cutting-edge tool. Companies may save time, money, and resources by streamlining Saphira AI’s certification process and automating report creation.

The post Saphira AI: An AI Platform that Revolutionizes Hardware Safety Compliance appeared first on MarkTechPost.

Source: Read MoreÂ