3D printing has come a long way since its invention in 1983 by Chuck Hull, who pioneered stereolithography, a technique that solidifies liquid resin into solid objects using ultraviolet lasers. Over the decades, 3D printers have evolved from experimental curiosities into tools capable of producing everything from custom prosthetics to complex food designs, architectural models, and even functioning human organs.

But as the technology matures, its environmental footprint has become increasingly difficult to set aside. The vast majority of consumer and industrial 3D printing still relies on petroleum-based plastic filament. And while “greener” alternatives made from biodegradable or recycled materials exist, they come with a serious trade-off: they’re often not as strong. These eco-friendly filaments tend to become brittle under stress, making them ill-suited for structural applications or load-bearing parts — exactly where strength matters most.

This trade-off between sustainability and mechanical performance prompted researchers at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) and the Hasso Plattner Institute to ask: Is it possible to build objects that are mostly eco-friendly, but still strong where it counts?

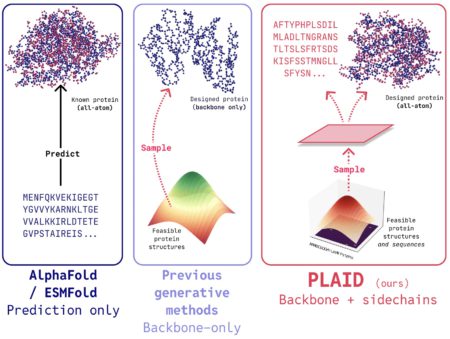

Their answer is SustainaPrint, a new software and hardware toolkit designed to help users strategically combine strong and weak filaments to get the best of both worlds. Instead of printing an entire object with high-performance plastic, the system analyzes a model through finite element analysis simulations, predicts where the object is most likely to experience stress, and then reinforces just those zones with stronger material. The rest of the part can be printed using greener, weaker filament, reducing plastic use while preserving structural integrity.

“Our hope is that SustainaPrint can be used in industrial and distributed manufacturing settings one day, where local material stocks may vary in quality and composition,” says MIT PhD student and CSAIL researcher Maxine Perroni-Scharf, who is a lead author on a paper presenting the project. “In these contexts, the testing toolkit could help ensure the reliability of available filaments, while the software’s reinforcement strategy could reduce overall material consumption without sacrificing function.”

For their experiments, the team used Polymaker’s PolyTerra PLA as the eco-friendly filament, and standard or Tough PLA from Ultimaker for reinforcement. They used a 20 percent reinforcement threshold to show that even a small amount of strong plastic goes a long way. Using this ratio, SustainaPrint was able to recover up to 70 percent of the strength of an object printed entirely with high-performance plastic.

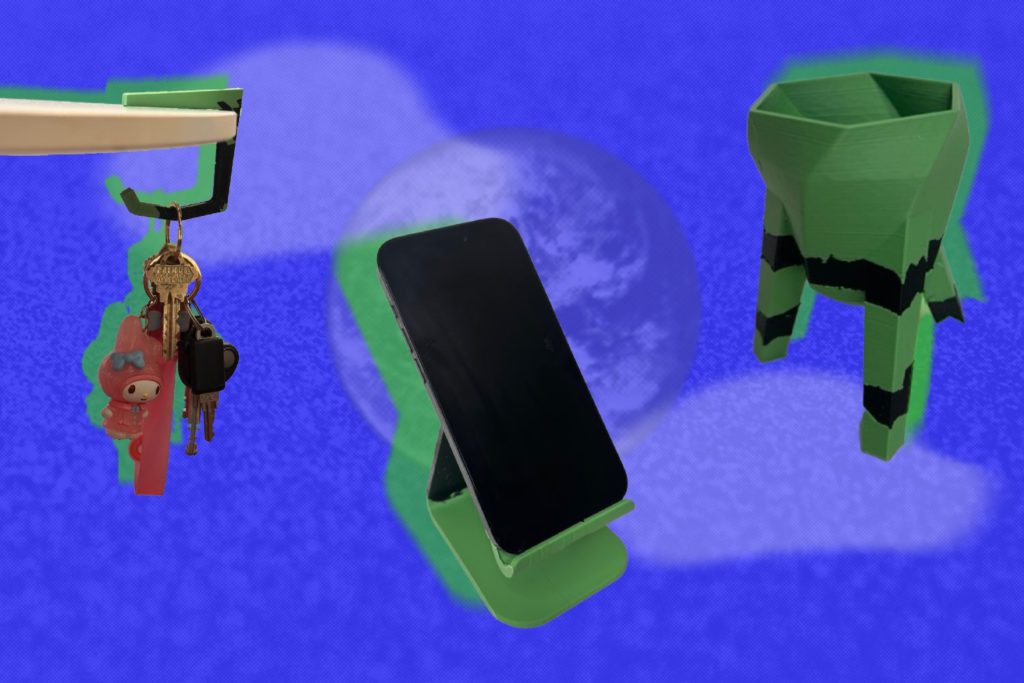

They printed dozens of objects, from simple mechanical shapes like rings and beams to more functional household items such as headphone stands, wall hooks, and plant pots. Each object was printed three ways: once using only eco-friendly filament, once using only strong PLA, and once with the hybrid SustainaPrint configuration. The printed parts were then mechanically tested by pulling, bending, or otherwise breaking them to measure how much force each configuration could withstand.

In many cases, the hybrid prints held up nearly as well as the full-strength versions. For example, in one test involving a dome-like shape, the hybrid version outperformed the version printed entirely in Tough PLA. The team believes this may be due to the reinforced version’s ability to distribute stress more evenly, avoiding the brittle failure sometimes caused by excessive stiffness.

“This indicates that in certain geometries and loading conditions, mixing materials strategically may actually outperform a single homogenous material,” says Perroni-Scharf. “It’s a reminder that real-world mechanical behavior is full of complexity, especially in 3D printing, where interlayer adhesion and tool path decisions can affect performance in unexpected ways.”

A lean, green, eco-friendly printing machine

SustainaPrint starts off by letting a user upload their 3D model into a custom interface. By selecting fixed regions and areas where forces will be applied, the software then uses an approach called “Finite Element Analysis” to simulate how the object will deform under stress. It then creates a map showing pressure distribution inside the structure, highlighting areas under compression or tension, and applies heuristics to segment the object into two categories: those that need reinforcement, and those that don’t.

Recognizing the need for accessible and low-cost testing, the team also developed a DIY testing toolkit to help users assess strength before printing. The kit has a 3D-printable device with modules for measuring both tensile and flexural strength. Users can pair the device with common items like pull-up bars or digital scales to get rough, but reliable performance metrics. The team benchmarked their results against manufacturer data and found that their measurements consistently fell within one standard deviation, even for filaments that had undergone multiple recycling cycles.

Although the current system is designed for dual-extrusion printers, the researchers believe that with some manual filament swapping and calibration, it could be adapted for single-extruder setups, too. In current form, the system simplifies the modeling process by allowing just one force and one fixed boundary per simulation. While this covers a wide range of common use cases, the team sees future work expanding the software to support more complex and dynamic loading conditions. The team also sees potential in using AI to infer the object’s intended use based on its geometry, which could allow for fully automated stress modeling without manual input of forces or boundaries.

3D for free

The researchers plan to release SustainaPrint open-source, making both the software and testing toolkit available for public use and modification. Another initiative they aspire to bring to life in the future: education. “In a classroom, SustainaPrint isn’t just a tool, it’s a way to teach students about material science, structural engineering, and sustainable design, all in one project,” says Perroni-Scharf. “It turns these abstract concepts into something tangible.”

As 3D printing becomes more embedded in how we manufacture and prototype everything from consumer goods to emergency equipment, sustainability concerns will only grow. With tools like SustainaPrint, those concerns no longer need to come at the expense of performance. Instead, they can become part of the design process: built into the very geometry of the things we make.

Co-author Patrick Baudisch, who is a professor at the Hasso Plattner Institute, adds that “the project addresses a key question: What is the point of collecting material for the purpose of recycling, when there is no plan to actually ever use that material? Maxine presents the missing link between the theoretical/abstract idea of 3D printing material recycling and what it actually takes to make this idea relevant.”

Perroni-Scharf and Baudisch wrote the paper with CSAIL research assistant Jennifer Xiao; MIT Department of Electrical Engineering and Computer Science master’s student Cole Paulin ’24; master’s student Ray Wang SM ’25 and PhD student Ticha Sethapakdi SM ’19 (both CSAIL members); Hasso Plattner Institute PhD student Muhammad Abdullah; and Associate Professor Stefanie Mueller, lead of the Human-Computer Interaction Engineering Group at CSAIL.

The researchers’ work was supported by a Designing for Sustainability Grant from the Designing for Sustainability MIT-HPI Research Program. Their work will be presented at the ACM Symposium on User Interface Software and Technology in September.

Source: Read MoreÂ