Wind turbines are a critical component in the shift away from fossil fuels toward more sustainable, green sources of energy. According to the International Energy Agency (IEA), the global capacity of wind energy has been growing rapidly, reaching over 743 gigawatts by 2023. Wind energy, in particular, has one of the greatest potentials to increase countries’ renewable capacity growth. Solar PV and wind additions are forecast to more than double by 2028 compared with 2022, continuously breaking records over the forecast period.

This growth highlights the increasing reliance on wind power and, consequently, the need for effective maintenance strategies. Keeping wind turbines operating at maximum capacity is essential to ensuring their continued contribution to the energy grid. Like any mechanical device, wind turbines must undergo periodic maintenance to keep them operating at optimal levels.

In recent years, advancements in technology—particularly in AI and machine learning—have played a significant role by introducing predictive maintenance breakthroughs to industrial processes like periodic maintenance. By integrating AI into renewable energy systems, organizations of all sizes can reduce costs and gain efficiencies.

In this post, we will dig into an AI application use case for real-time anomaly detection through sound input, showcasing the impact of AI and MongoDB Atlas Vector Search for predictive maintenance of wind turbines.

Predictive Maintenance in Modern Industries

Companies increasingly invest in predictive maintenance to optimize their operations and drive efficiency. Research from Deloitte indicates that predictive maintenance can reduce equipment downtime by 5–15 percent, increase labor productivity by 5–20 percent, and reduce overall new equipment costs by 3–5 percent. This helps organizations maximize their investment in equipment and infrastructure.

By implementing predictive maintenance strategies, companies can anticipate equipment failures before they occur, ultimately resulting in longer equipment lifetimes, tighter budget control, and higher overall throughput. More concretely, businesses aim to reduce mean time to repair, optimal ordering of replacement parts, efficient people management, and reduced overall maintenance costs. Leveraging data interoperability, real-time analysis, modeling and simulation, and machine learning techniques, predictive maintenance enables companies to thrive in today’s competitive landscape.

However, despite its immense potential, predictive maintenance also presents significant challenges. One major hurdle is the consolidation of heterogeneous data, as predictive maintenance systems often need to integrate data from various formats and sources that can be difficult to integrate. Scalability also becomes a concern when dealing with the high volumes of IoT signals generated by numerous devices and sensors. And lastly, managing and analyzing this vast amount of data in real-time poses challenges that must be overcome to realize the full benefits of predictive maintenance initiatives.

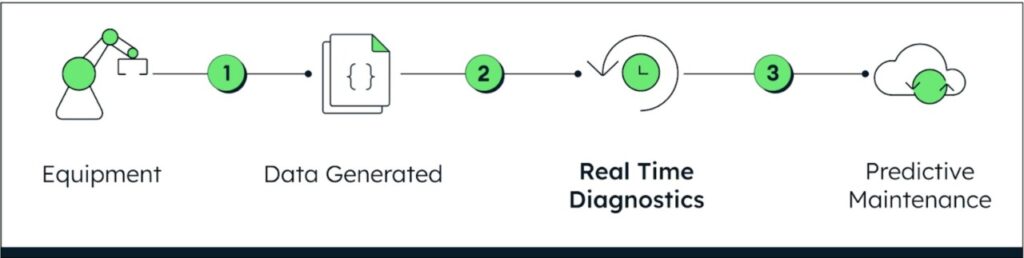

At its core, predictive maintenance begins with real-time diagnostics, enabling proactive identification and mitigation of potential equipment failures in real-time.

Figure 1: Predictive Maintenance starts with real-time diagnostics

However, while AI has been employed for real-time diagnostics for some time, the main challenge has been acquiring and utilizing the necessary data for training AI models. Traditional methods have struggled with incorporating unstructured data into these models effectively.

Enter gen AI and vector search technologies, positioned to revolutionize this landscape. Flexible data platforms working together with AI algorithms can help generate insights from diverse data types, including images, video, audio, geospatial data, and more, paving the way for more robust and efficient maintenance strategies. In this context, MongoDB Atlas Vector Search stands out as a foundational element for effective and efficient gen AI-powered predictive maintenance models.

Why MongoDB and Atlas Vector Search?

For several reasons, MongoDB stands out as the preferred database solution for modern applications.

Figure 2: MongoDB Atlas Developer Data Platform

Document data model

One of the reasons why the document model is well-suited to the needs of modern applications is its ability to store diverse data types in BSON (Binary JSON) format, ranging from structured to unstructured. This flexibility essentially eliminates the middle layer necessary to convert to a SQL-like format, resulting in easier-to-maintain applications, lower development times, and faster response to changes.

Time series collections

MongoDB excels in handling time-series data generated by edge devices, IoT sensors, PLCs, SCADA systems, and more. With dedicated time-series collections, MongoDB provides efficient storage and retrieval of time-stamped data, enabling real-time monitoring and analysis.

Real-time data processing and aggregation

MongoDB’s adeptness in real-time data processing is crucial for immediate diagnostics and responses, ensuring timely interventions to prevent costly repairs and downtime. Its powerful aggregation capabilities facilitate the synthesis of data from multiple sources, providing comprehensive insights into fleet-wide performance trends.

Developer data platform

Beyond just storing data, MongoDB Atlas is a multi-cloud developer data platform, providing the flexibility required to build a diverse range of applications. Atlas includes features like transactional processing, text-based search, vector search, in-app analytics, and more through an elegant and integrated suite of data services. It offers developers a top-tier experience through a unified query interface, all while meeting the most demanding requirements for resilience, scalability, and cybersecurity.

Atlas Vector Search

Among the out-of-the-box features offered by MongoDB Atlas, Atlas Vector Search stands out, enabling the search of unstructured data effortlessly. You can generate vector embeddings with machine learning models like the ones found in OpenAI or Hugging Face, and store and index them in Atlas. This feature facilitates the indexing of vector representations of objects and retrieves those that are semantically most similar to your query.

Explore the capabilities of Atlas Vector Search.

This functionality is especially interesting for unstructured data that was previously hard to leverage, such as text, images, and audio, allowing searches that combine audio, video, metadata, production equipment data, or sensor measurements to provide an answer to a query.

Let’s delve into how simple it is to leverage AI to significantly enhance the sophistication of predictive maintenance models with MongoDB Atlas.

Real-time audio-based diagnostics with Atlas Vector Search

In our demonstration, we’ll showcase real-time audio-based diagnostics applied to a wind turbine. It’s important to note that while we focus on wind turbines here, the concept can be extrapolated to any machine, vehicle, or device emitting sound. To illustrate this concept, we’ll utilize a handheld fan as our makeshift wind turbine.

Wind turbines emit different sounds depending on their operational status. By continuously monitoring the turbine’s audio, our system can accurately specify the current operational status of the equipment and reduce the risk of unexpected breakdowns. Early detection of potential issues allows for enhanced operational efficiency, minimizing the time and resources required for manual inspections. Additionally, timely identification can prevent costly repairs and reduce overall turbine downtime, thus enhancing cost-effectiveness.

Now, let’s have a look at how this demo works!

Figure 3: Application Architecture

Audio Preparation

We begin by capturing the audio from the equipment in different situations (normal operation, high vs. low load, equipment obstructed, not operating, etc.).

Once each sound is collected, we use an embedding model to process the audio data to convert it to a vector. This step is crucial because by generating embeddings for each audio track, which are high-dimensional vector representations, we are essentially capturing the unique characteristics of the sound.

We then upload these vector embeddings to MongoDB Atlas. By adding just a few examples of sounds in our database, they are ready to be searched (and essentially compared) with the sound emitted by our equipment during its operation in real-time.

Audio-based diagnosis

Now, we put our equipment into normal operation and start capturing the sound it is making in real-time. In this demonstration, we capture one-second clips of audio. Then, with the same embedding model used before, we take our audio clips and convert them to vector embeddings in real-time. This process happens in milliseconds, allowing us to have real-time monitoring of the audio. The one-second audio clips, now converted to vector embeddings, are then sent to MongoDB Atlas Vector Search, which can search for and find the most similar vectors from the ones we previously recorded in our audio preparation phase. The result is given back with a percentage of similarity, enabling a very accurate prediction of the current status of the operation of the wind turbine.

These steps are performed repeatedly every second, leveraging fast embedding of vectors and quick searches, allowing for real-time monitoring based on sound.

Check out the video below to see it in action!

Transforming Predictive Maintenance with AI and MongoDB

Predictive maintenance offers substantial benefits but poses challenges like data integration and scalability. MongoDB stands out as a preferred database solution, offering scalability, flexibility, and real-time data processing. As technology advances, AI integration promises to further revolutionize the industry.

Thank you to Ralph Johnson and Han Heloir for their valuable contributions to this demo!

Ready to revolutionize your predictive maintenance strategy with AI and MongoDB Atlas Vector Search?

Try it out yourself by following the simple steps outlined in our Github repo!

Explore how MongoDB empowers manufacturing operations by visiting these resources:

Transforming Industries with MongoDB and AI: Manufacturing and Motion

MongoDB for Automotive: Driving Innovation from Factory to Finish Line

Source: Read More