When Nikola Tesla predicted we’d have handheld phones that could display videos, photographs, and more, his musings seemed like a distant dream. Nearly 100 years later, smartphones are like an extra appendage for many of us.

Digital fabrication engineers are now working toward expanding the display capabilities of other everyday objects. One avenue they’re exploring is reprogrammable surfaces — or items whose appearances we can digitally alter — to help users present important information, such as health statistics, as well as new designs on things like a wall, mug, or shoe.

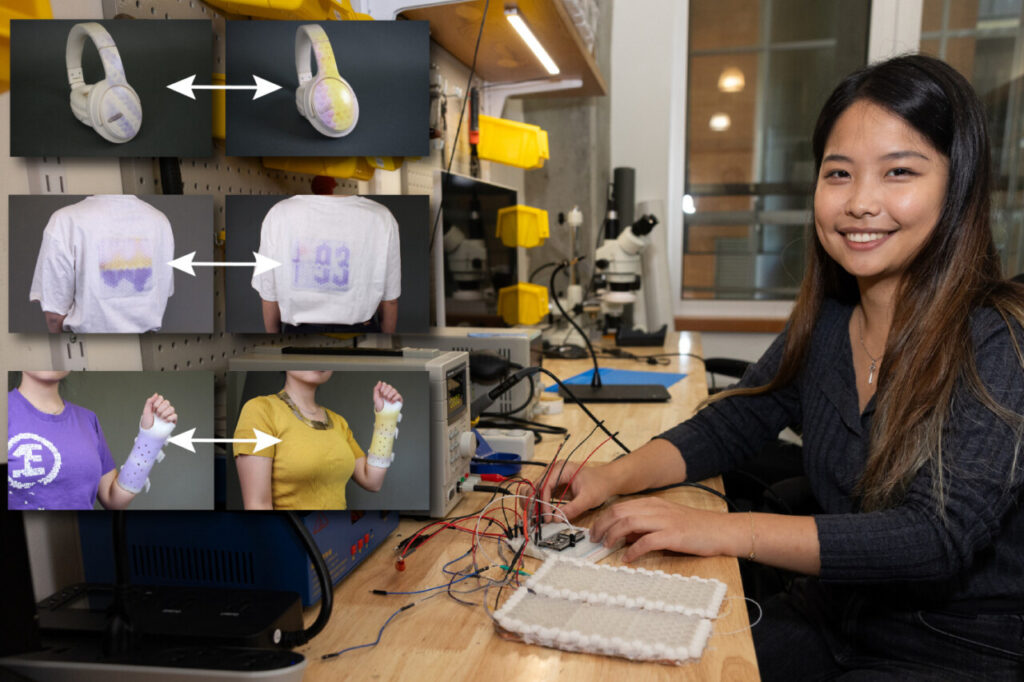

Researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL), the University of California at Berkeley, and Aarhus University have taken an intriguing step forward by fabricating “PortaChrome,†a portable light system and design tool that can change the color and textures of various objects. Equipped with ultraviolet (UV) and red, green, and blue (RGB) LEDs, the device can be attached to everyday objects like shirts and headphones. Once a user creates a design and sends it to a PortaChrome machine via Bluetooth, the surface can be programmed into multicolor displays of health data, entertainment, and fashion designs.

To make an item reprogrammable, the object must be coated with photochromic dye, an invisible ink that can be turned into different colors with light patterns. Once it’s coated, individuals can create and relay patterns to the item via the team’s graphic design software, or use the team’s API to interact with the device directly and embed data-driven designs. When attached to a surface, PortaChrome’s UV lights saturate the dye while the RGB LEDs desaturate it, activating the colors and ensuring each pixel is toned to match the intended design.

Zhu and her colleagues’ integrated light system changes objects’ colors in less than four minutes on average, which is eight times faster than their prior work, “Photo-Chromeleon.†This speed boost comes from switching to a light source that makes contact with the object to transmit UV and RGB rays. Photo-Chromeleon used a projector to help activate the color-changing properties of photochromic dye, where the light on the object’s surface is at a reduced intensity.

“PortaChrome provides a more convenient way to reprogram your surroundings,†says Yunyi Zhu ’20, MEng ’21, an MIT PhD student in electrical engineering and computer science, affiliate of CSAIL, and lead author on a paper about the work. “Compared with our projector-based system from before, PortaChrome is a more portable light source that can be placed directly on top of the photochromic surface. This allows the color change to happen without user intervention and helps us avoid contaminating our environment with UV. As a result, users can wear their heart rate chart on their shirt after a workout, for instance.â€

Giving everyday objects a makeover

In demos, PortaChrome displayed health data on different surfaces. A user hiked with PortaChrome sewed onto their backpack, putting it into direct contact with the back of their shirt, which was coated in photochromic dye. Altitude and heart rate sensors sent data to the lighting device, which was then converted into a chart through a reprogramming script developed by the researchers. This process created a health visualization on the back of the user’s shirt. In a similar showing, MIT researchers displayed a heart gradually coming together on the back of a tablet to show how a user was progressing toward a fitness goal.

PortaChrome also showed a flair for customizing wearables. For example, the researchers redesigned some white headphones with sideways blue lines and horizontal yellow and purple stripes. The photochromic dye was coated on the headphones and the team then attached the PortaChrome device to the inside of the headphone case. Finally, the researchers successfully reprogrammed their patterns onto the object, which resembled watercolor art. Researchers also recolored a wrist splint to match different clothes using this process.

Eventually, the work could be used to digitize consumers’ belongings. Imagine putting on a cloak that can change your entire shirt design, or using your car cover to give your vehicle a new look.

PortaChrome’s main ingredients

On the hardware end, PortaChrome is a combination of four main ingredients. Their portable device consists of a textile base as a sort of backbone, a textile layer with the UV lights soldered on and another with the RGB stuck on, and a silicone diffusion layer to top it off. Resembling a translucent honeycomb, the silicone layer covers the interlaced UV and RGB LEDs and directs them toward individual pixels to properly illuminate a design over a surface.

This device can be flexibly wrapped around objects with different shapes. For tables and other flat surfaces, you could place PortaChrome on top, like a placemat. For a curved item like a thermos, you could wrap the light source around like a coffee cup sleeve to ensure it reprograms the entire surface.

The portable, flexible light system is crafted with maker space-available tools (like laser cutters, for example), and the same method can be replicated with flexible PCB materials and other mass manufacturing systems.

While it can also quickly convert our surroundings into dynamic displays, Zhu and her colleagues believe it could benefit from further speed boosts. They’d like to use smaller LEDs, with the likely result being a surface that could be reprogrammed in seconds with a higher-resolution design, thanks to increased light intensity.

“The surfaces of our everyday things are encoded with colors and visual textures, delivering crucial information and shaping how we interact with them,†says Georgia Tech postdoc Tingyu Cheng, who was not involved with the research. “PortaChrome is taking a leap forward by providing reprogrammable surfaces with the integration of flexible light sources (UV and RGB LEDs) and photochromic pigments into everyday objects, pixelating the environment with dynamic color and patterns. The capabilities demonstrated by PortaChrome could revolutionize the way we interact with our surroundings, particularly in domains like personalized fashion and adaptive user interfaces. This technology enables real-time customization that seamlessly integrates into daily life, offering a glimpse into the future of ‘ubiquitous displays.’â€

Zhu is joined by nine CSAIL affiliates on the paper: MIT PhD student and MIT Media Lab affiliate Cedric Honnet; former visiting undergraduate researchers Yixiao Kang, Angelina J. Zheng, and Grace Tang; MIT undergraduate student Luca Musk; University of Michigan Assistant Professor Junyi Zhu SM ’19, PhD ’24; recent postdoc and Aarhus University assistant professor Michael Wessely; and senior author Stefanie Mueller, the TIBCO Career Development Associate Professor in the MIT departments of Electrical Engineering and Computer Science and Mechanical Engineering and leader of the HCI Engineering Group at CSAIL.

This work was supported by the MIT-GIST Joint Research Program and was presented at the ACM Symposium on User Interface Software and Technology in October.

Source: Read MoreÂ